By Cindy Peterson

How a Lake County Farm Brought Cigar Tobacco Back to Florida

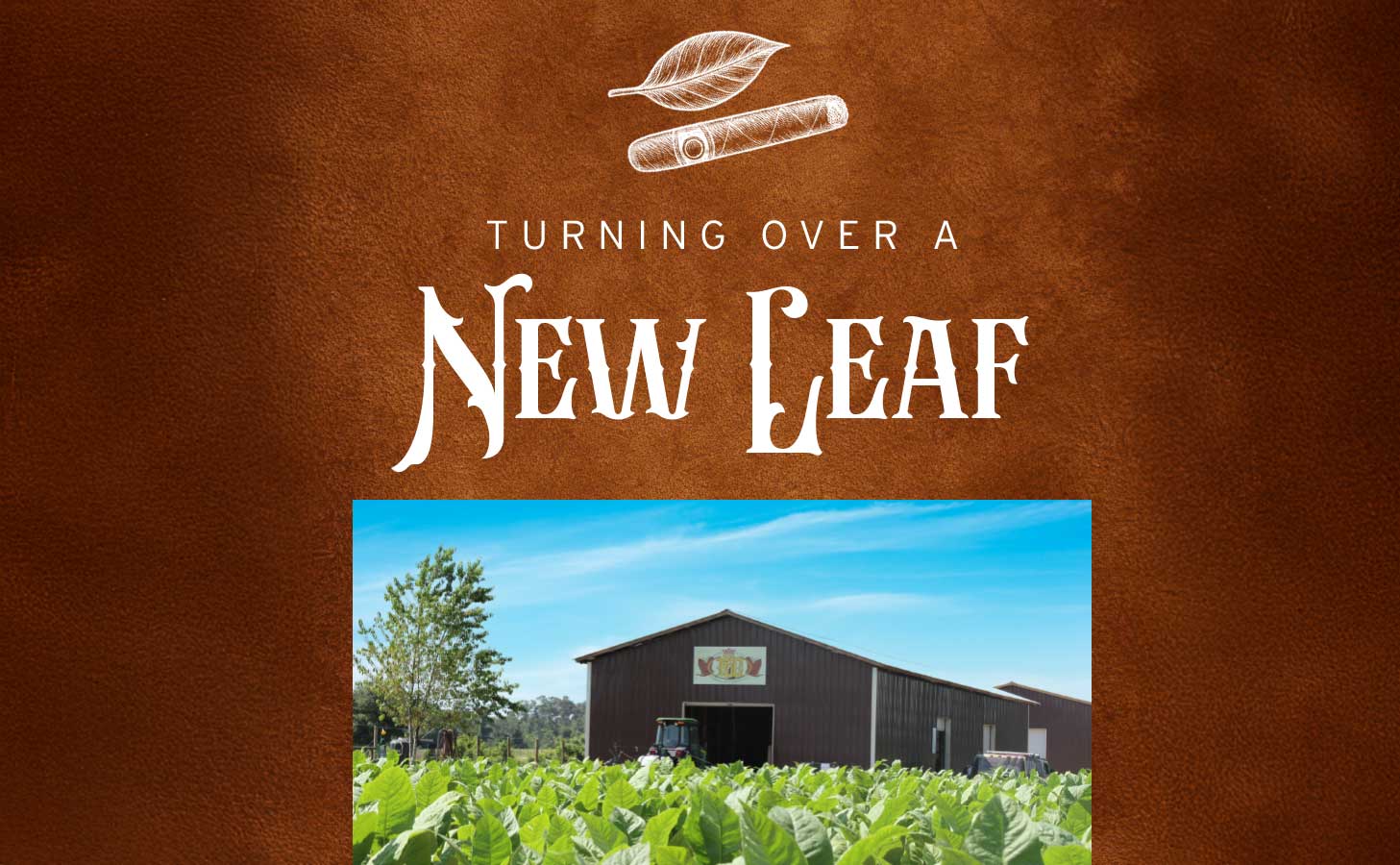

Florida cultivated some of the world’s finest cigar tobacco for nearly 175 years, but production dropped over four decades ago as rising costs and urban sprawl began taking over farmland.

But the cigar tobacco industry didn’t go up in smoke. Today, a Clermont farm is aiming to restore that legacy.

Florida Sun Grown, a 20-acre operation in Clermont, is the first Florida farm since 1977 to produce long-filler cigar tobacco.

Jeff Borysiewicz, whose path to farming premium cigar tobacco runs through the retail side of the industry, is on a mission is to revive a uniquely Florida tradition on a modern, small-batch scale and deliver distinctive, high-quality leaf that can stand proudly in premium blends.

“I own Corona Cigar Company, which I started in 1996 out of an extra bedroom in my house. It was originally a mail order company that ended up taking off,” says Borysiewicz, Corona’s president and founder.

He grew the catalog business into a network of destination cigar stores and bars, and now has six locations across Central Florida and the Gulf Coast.

By 2013, Jeff decided to test grow long-filler cigar tobacco in Florida again, but on a scale that matches today’s economics.

“In 2013, we purchased this farm and it was a test crop of growing cigar tobacco,” he says. “It’s not that it couldn’t be done, but could it be profitable? It takes a lot of work and many hands to go from seed to cigar.”

The idea wasn’t to replace the vast Central American supply chain, but rather to add a distinctive Florida note to select premium blends and rekindle a nearly lost chapter of American agriculture.

From Seed to Cigar

At Florida Sun Grown, the life of a tobacco leaf begins in the nursery with tobacco seeds are the size of a grain of pepper that must be cultivated into a healthy starter with lots of roots to be chosen for planting.

“We start with a little tiny tobacco seed that we literally send to California to have it pelletized first,” Jeff says.

Pelletizing makes the speck-size seeds big enough for greenhouse trays and automated seeders. Healthy seedlings develop in a tightly controlled environment before being transplanted to the field.

Once established in the field, the plants hit “knee high” in roughly 30–45 days. Then the growth explodes.

“It’ll grow sometimes six inches overnight,” Jeff says.

The crew then tops the plants, removing the flower, and applies a growth regulator so the plant pushes energy into bigger leaves rather than seed production.

The crop schedule is built around Florida’s weather windows. For the fall crop, planting begins the first week of September for a November to January harvest.

“Tobacco can’t survive frost, and summer’s heat and rainfall are too much,” Jeff says. “Spring crops are possible and we normally do another round then as well.”

Though the farm totals about 20 acres, the labor is anything but small. Jeff estimates that a single tobacco leaf will go through about 300 hands, from field work, curing, sorting, fermentation, rolling, banding, and boxing, all across multiple countries and years.

Florida Sun Grown, as the name suggests, uses “sun grown” methods with no shade tents. This mirrors similar operations in Cuba and Central America.

After the Harvest

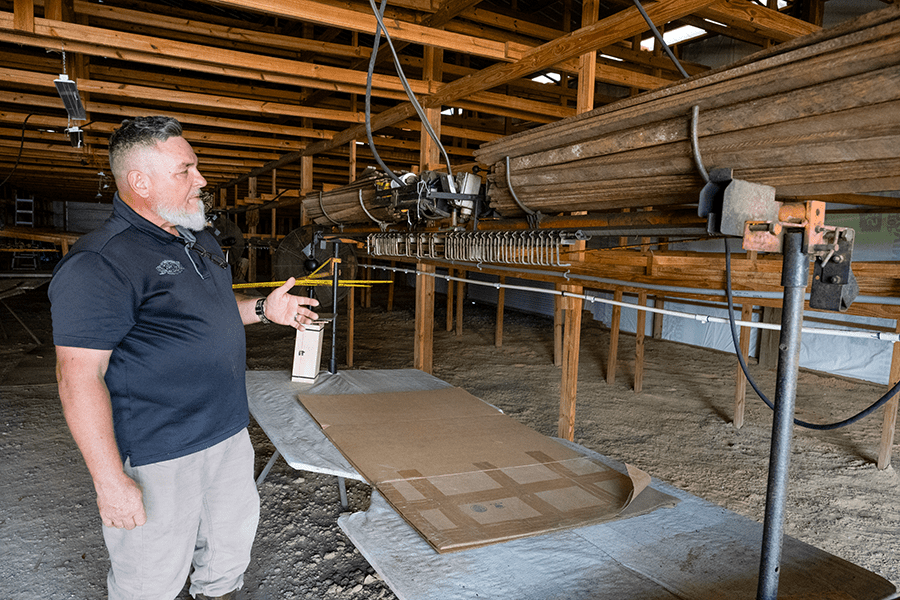

Fresh-cut leaves arrive at FSG’s curing barn, which houses mid-century sewing rigs salvaged from a Connecticut shade farm. Here the freshly harvested tobacco leaves are stitched onto lath sticks and hung to yellow and then fully brown as chlorophyll dissipates.

“Sixty days later, they’re fully cured, meaning all the green is out of them,” Jeff says. From there, the cured leaf is packed into 100-lb. cartons, placed in a shipping container, inspected, fully fumigated and exported. Most FSG tobacco heads to partner factories in Nicaragua for the long, hands-on steps of fermentation, sorting, de-stemming and aging.

Fermentation turns stacks of moistened leaf, meticulously layered by hand, into aromatically clean, smoke-ready tobacco as ammonia and harsh nitrates dissipate.

“That process is repeated over and over and over for over a year,” he says.

Temperatures are monitored and teams break down the piles and rebuild them before heat spikes turn fermentation into compost. After fermentation, the leaf is packed and goes into aging for two years.

“Three years later, the tobacco is going to get sorted again,” Jeff says.

Then the center vein, or stem, is removed. A fun historical fact about the people doing that work is that they were called “strippers” in cigar factories.

Hand-Rolling Perfection

All leaves don’t become the glamorous outer wrapper. Only the most cosmetically perfect and elastic sheets earn that job. Others serve as binder, holding the cigar’s bunch – or filler – together.

“The wrapper on a cigar must be perfect because it’s the most visual part,” Jeff says.

After wrapping, the flavors begin to come alive. Blending combines leaves of different textures and strengths from different seed varieties and growing positions on the plant, plus different countries of origin. Tobacco from the bottom of the plant is thinner and milder; the top leaves are thicker and more potent but rarely supple enough to serve as wrapper. Every variable shapes how a finished cigar smells, tastes and burns.

FSG tobacco appears in several finished lines. FSG by Drew Estate Cigars is their signature brand. The widely distributed “20 Acre Farm” is made by Drew Estate with FSG in the blend—one of several factory partners the brand works with—and “The American,” rolled by the J.C. Newman family in Tampa’s historic El Reloj factory, uses FSG wrapper, which is re-imported from Nicaragua after processing. As Jeff noted, different factories possess different libraries of aged leaf. The same FSG tobacco can express differently depending on a partner’s house inventory and technique.

Not every Florida leaf leaves Florida. In Orlando, a small team hand rolls “FSG Farm Roll” cigars made from FSG wrapper, binder and filler—100% Florida tobacco—that’s been aging in single-barrel bourbon casks. The brand’s limited-production philosophy mirrors craft spirits with distinctive, small runs that emphasize place and process over mass volume.

Inside the Lounge

Today, you’ll find the finished product in premium cigar lounges, paired with whiskey and bourbon. Corona Cigar’s rooms are designed for conversation as much as commerce, something Jeff says he really takes pride in.

“If you go to Corona Cigar right now, you’ll see a hundred people in there smoking cigars, talking with each other, creating mentoring relationships between old and young,” he says. “It’s a way to relax and really get conversation going. We need more of that in today’s society.”

Photos: Cindy Peterson & Provided

Originally from the small town of Berryville, Arkansas, Cindy has become a multimedia specialist in journalism, photography, videography, and video editing. She has a B.S. in Communications from the University of Central Arkansas and produces Style Magazine's Sports Hub Podcast and the Healthy Living Podcast. She also produces for Beacon College’s Telly Award-winning PBS show, “A World of Difference.” When she isn’t working, Cindy loves traveling the National Parks with her husband , Ryan, and son, David, photographing wildlife.